Risk assessment, choosing the right technology and properly educating operators are the first steps to prevent explosion hazards. In this blog article, we will explain how you ensure safe weighing in hazardous areas.

In the chemical, petrochemical and pharmaceutical industries, for example, but also in port areas, the paint industry, the food industry and environments with flammable gases, antistatic materials, dust and water, strict safety guidelines must be met and ATEX certification is required. Adequate training and the choice of appropriate technologies are two pillars for preventing explosions in daily operations. As the world's largest Dutch manufacturer of mobile and integrated weighing systems for forklift trucks, pallet trucks and other material handling equipment, RAVAS is an acknowledged specialist in this field.

Potential hazards

In hazardous areas, dangers have many different origins, such as the materials used or the negligence of operators. The presence of flammable gases for example significantly increases potential hazards. For gases, such as methane, propane, butane, hydrogen or liquid vapours like petrol or solvents, explosion limits exist. These limits indicate the range in which an explosion is possible.

Furthermore, a spark or flame with sufficient energy counts as a potential risk. And the ignition temperature of a combustible substance can be a danger. The ignition temperature of a combustible substance is the lowest temperature at which, under specified conditions, ignition of a combustible substance in the form of a gas or vapour mixture with air will occur. And finally, of course also human errors can lead to an explosion, such as the wrong use of equipment or operators who fail to follow safety procedures.

Taking the above into account, also the use of a single hand pallet truck or electric pallet truck equipped with a mobile weighing system, can pose a risk.

How to ensure safe weighing and prevent explosions

To effectively manage explosion pareas, preventive measures must be taken, and specific solutions must be incorporated. To ensure safe weighing processes, it is important to use certified and compliant equipment, prevent the formation of sparks, control the temperature of the environment, properly maintain machinery and train staff. These are the steps you should take to ensure safe weighing in hazardous environments:

- Before carrying out any operations, identify areas that may pose an explosion risk, which are identified as "ATEX zones" according to the safety regulations.

- Just like rooms, also your material handling equipment must comply with ATEX directives. RAVAS offers different solutions that are suitable for different applications, such as batching, dosing, and mixing, and available in ATEX certified versions.

- To prevent the development of sparks, it is important to use anti-static systems and ensure that the pallet truck is properly grounded. In addition, it is important that mobile weighing systems are never a source of ignition by generating heat, thus contributing to the ignition temperature of a flammable substance or mixture.

- Regular maintenance and cleaning are required for a proper and safe operation, especially when it comes to the removal of dust and flammable substances that may accumulate.

Solutions for safe weighing

Based on years of experience, RAVAS has designed solutions to weigh palletized goods in het flow of your logistical or supply chain process. Mobile weighing allows you to rely on accurate, real-time weighing data while transporting loads on forklift trucks, pallet trucks and other material handling equipment. RAVAS weighing solutions are used in hazardous environments because they cannot be a source of explosion. Ever. These systems are designed for maximum safety, with anti-static materials, protection against dust and water and compliance with ATEX directives.

RAVAS weighing solutions can be used in various areas with explosion hazards, such as in the chemical, petrochemical and pharmaceutical industries or in any area where flammable gases may be present. Robustness and precision make them an excellent weighing solution and mobility allows them to be used anywhere.

Examples of state-of-the-art pallet trucks

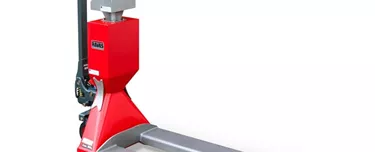

Many RAVAS customers rely on their weighing solutions such as the RAVAS-2100 EXi and the ProLine-2100 EXi. Both explosion-proof hand pallet trucks with 2 main benefits: maximum precision and optimal manoeuvrability.

The RAVAS-2100 EXi consists of stainless-steel and is designed for filling, mixing, and dispensing in hazardous environments, as certified by ATEX in zones 1/21. This weighing EXi hand pallet truck is easy to use thanks to its practical display and switches off automatically if not used for three minutes. Depending on customer requirements, there is the option of an all-stainless-steel instrument with adjustable indicators and large buttons for use even with gloves on.

Sharing many of these features, the ProLine-2100Exi is also a manual pallet truck for highly accurate mobile weighing thanks to its patented FlexBolts technology. It is also suitable for industrial applications and is available with Bluetooth to transfer data to a computer or printer outside the hazardous area. Tracking and quality control are thus its added value.

Learn more about our Mobile Weighing technology

Through blogs, videos and other items, discover how a mobile weighing system can make your processes more efficient and cost-effective, generate management information, monitor the quality of your products and services and promote customer satisfaction.