overcome the challenges

Plan today for the roadblocks up ahead

Several challenges are likely to affect the warehouse logistics industry in 2024. As companies strive to enhance efficiency and reduce costs, they are increasingly confronted with critical issues such as maintaining inventory accuracy, optimizing storage space, streamlining data collection processes, and addressing inefficiencies at loading docks. These obstacles not only impede operational efficiency but also affect the bottom line. Let’s take a deep dive into these challenges and help you identify solutions that keep your process running smoothly.

Reduce Inventory Errors

Inventory accuracy is crucial in logistics as it directly impacts order fulfillment, customer satisfaction, and overall operational efficiency. Human errors such as miscounting, misplacement of items, incorrect data entry, and picking/packing mistakes can lead to discrepancies in inventory records.

Managing diverse product categories with varying sizes, weights, expiration dates, and storage requirements adds complexity to inventory management and increases the risk of error.

Implementing real-time inventory tracking and monitoring solutions helps maintain visibility across the supply chain, detect discrepancies promptly, and take corrective actions. Enhancing inventory accuracy reduces costs, improves customer satisfaction, and optimizes overall operational efficiency.

Optimize Space

Logistics space optimization is essential for maximizing warehouse efficiency, reducing costs, and improving overall supply chain performance. Incorporating data-driven analysis, maximizing vertical storage, incorporating cross-docking strategies, and process automation are critical to reducing storage time, efficiently moving high-demand products, and eliminating redundancies.

However, restrictions posed by handling equipment can limit the ability to utilize space effectively.

Technologies such as mobile weighing systems can be leveraged to streamline workflows, reduce human errors, limit handling, and optimize space usage. Mobile weighing systems enable accurate weight measurements of incoming and outgoing goods. This information allows for better allocation of storage space based on weight considerations, such as storing heavier items at lower levels or optimizing shelving configurations to accommodate varying load weights efficiently. Also, mobile weighing systems contribute to precise inventory management by accurately weighing inventory items during receipt, picking, or shipping processes.

Improve Operational Efficiency

The loading dock is a critical area in logistics where goods are transferred between vehicles and the warehouse or directly to another vehicle when cross-docking. Bottlenecks in this area can significantly impact operational efficiency. Insufficient or outdated loading dock equipment, such as forklifts and pallet jacks, can impact efficiency, increase errors, and contribute to bottlenecks.

Upgrades to modern, efficient equipment, such as an electric pallet jack scale with weighing and data tracking technology, will improve the loading dock's productivity, speed, and accuracy. Upgrading equipment doesn't just benefit your organization's bottom line; it can also significantly impact employee satisfaction and productivity.

Streamline Data Collection

Data collection is critical in optimizing supply chain operations, improving decision-making, and enhancing overall efficiency.

Timely access to real-time data is crucial for effective and responsive supply chain management. However, data latency, system lags, and synchronization issues may hinder real-time data availability.

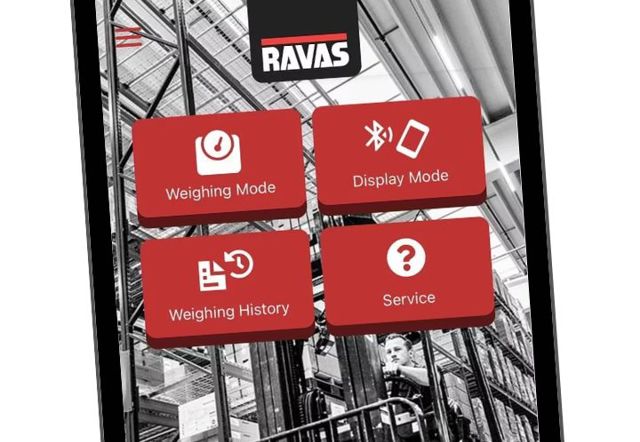

Deploying real-time monitoring and analytics tools to track logistics and supply chain events in real time enables proactive decision-making and responsiveness. Mobile weighing systems provide real-time weight data for pallets, containers, or goods being loaded or unloaded. This technology can also be integrated with warehouse management systems (WMS) or enterprise resource planning (ERP) systems, enabling data analysis and insights into weight-related metrics. The data integration supports informed decision-making and load optimization strategies and allows for errors to be corrected in real-time.

A smarter way to weigh

The logistics industry is all about adding intelligence to processes. With margins so small, companies have to make their business processes smarter to be competitive. In other words, data management is becoming crucial to improve efficiency and productivity. Mobile weighing technology is a highly effective way to achieve that goal. Your real-time data is always available by adding weighing systems to your current warehouse and forklift trucks or purchasing their pre-equipped counterparts.