-

- Industries

-

Production

Mobile weighing in production

Discover how mobile weighing in production processes saves time, reduces errors and improves quality control. Smart, fast and right on the shop floor.

More control. Less wasted time.

Mobile weighing in production

The manufacturing industry is all about speed and precision. You work with tight schedules, multiple production steps and often small margins for error. Every moment counts, and any deviation can affect quality or costs.

By mobile weighing, you make the process easier and faster. You weigh directly while moving or processing materials, without detours to fixed weighing stations. That means fewer interruptions, fewer errors and more control over your production process.

Without interruption

Fast and accurate weighing

Production processes require speed, accuracy and control. You want to be sure that each part has the right amount, without bringing work to a halt. With mobile weighing, you do this directly on the shop floor, while moving or processing goods.

This saves time, prevents errors and gives you up-to-date information about the weight of semi-finished or finished products. This is also important for quality control: you can immediately see if a batch deviates from the norm. Do you use the weight for internal settlement or invoicing? Then a Legal for Trade (OIML) approval is often required.

- Faster work: no more detours to fixed scales

- Fewer errors: direct control during production

- Higher quality: deviations quickly recognized

- Always up-to-date data: link with your ERP or production system

- Complies with legislation: suitable for Legal for Trade applications

Richard Busscher, Product Manager at RAVAS

"Many companies in the manufacturing industry are looking for ways to work faster without sacrificing accuracy. By using mobile weighing during the production process, they not only save time, but also increase quality and grip on their inventory."

This is how weighing makes a difference

Applications in the workplace

Mobile weighing is applicable at many times in the production process. By weighing at the right moment, you prevent errors, work faster and keep an overview of material use and output. Whether you are working with loose parts, liquids, semi-finished or packed products: mobile weighing helps you keep the process running smoothly.

Check incoming goods

Weigh on receipt to check that the weight delivered is correct.

Track raw material consumption

Keep track of exactly how much material is used in production.

Mixing and dispensing

Instantly add the correct quantities without additional handling.

Quality control

Intermediate check that the weight of products is within the set margin.

Shipping control

Check the final weight of pallets or batches before they leave the factory.

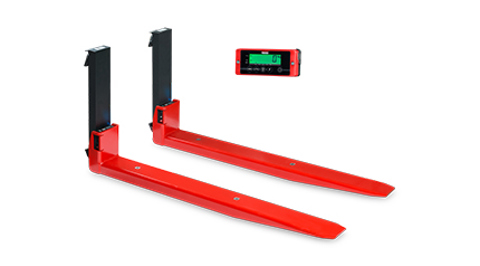

RAVAS iForks-32

The RAVAS iForks-32 makes accurate weighing during forklift transport easy, completely wireless and uninterrupted.

- Easy installation

- Standard with wireless connectivity

- Optional: NTEP certification or extra thin forks

RAVAS iCP-32

Robust heavy-duty forklift scale equipped with RAVAS 320 indicator, which measures accurately and can be attached to most types of forklifts.

- Weighing capacity: 5,000 lbs., 10,000 lbs. or 12,000 lbs.

- Scale section: 5,000 lbs to 12.000 lbs.

- Fits almost all forklifts without structural modifications

- Available in both wired and wireless versions

RAVAS RCS Hy-Q-52

The RAVAS RCS Hy-Q-52, a user-friendly hydraulic weighing system with intuitive 5200 touchscreen indicator. Suitable for accurate hydraulic weighing.

- Equipped with a touchscreen indicator

- With overload indication

- To weigh very accurately

Customer Story

Smurfit Kappa

At Smurfit Kappa Van Mierlo, mobile weighing with the iForks helps to accurately measure waste streams in the production process. With real-time data per production line and linking to the ERP system, the team gains more insight, less waste and better control over costs. Read the full story and find out how Smurfit Kappa optimized its production process.

Blog

A mobile weighing system as an alternative to the traditional scale

In transportation, every minute counts, and standing still at a fixed weighbridge takes time, space and manpower. In this blog you will read how a mobile weighing system offers an efficient and cost-saving alternative to the classic industrial scale. Ideal for companies that want faster loading, real-time visibility and more accuracy.

Consultation

Would you like personalised advice?

Our specialised team would be happy to tell you more about what mobile weighing can do for your production organisation.