-

- Customer Stories

-

Business case Frit Ravich: batching and dosing using mobile weighing technology

Frit Ravich uses RAVAS mobile weighing systems for their batching and dosing process

It is very likely that you have eaten some of the snacks of the customer we helped in this case study. We’re talking about Frit Ravich, producer and distributor of crisps and snacks. Thanks to mobile weighing technology, they have been able to know to the millimetre what happens before, during and after the batching process.

Challenge

What did Frit Ravich want to improve?

Before using RAVAS weighing systems, Frit Ravich started the production process with a number of kgs of raw material but did not control how much of the final product would come out of it.

Shortage or surplus errors were observed after production was finished. Product was missing to complete the order or there were units left over and there was no order to assign that surplus to. Loss of raw material.

We spoke with Narcís, Frit Ravich's warehouse manager. He tells us that there were losses in production. There were differences in the kg of raw material used and the kg of material produced at the end. Sometimes there was a lack of quantity to complete the order and sometimes there was excess. This required a re-run of the manufacturing process to complete an order or save unnecessary stock.

Investments in hardware and software

To optimize their processes, Frit Ravich invested in iForks-32, a RAVAS-3200 weighing hand pallet truck with WiFi and RAVAS Integration Software to integrate their data into their WMS.

Mobile Weighing Solutions

Products

The RAVAS-3200 is a hand pallet truck with extended weighing functions, optionally OIML approved for commercial weighing.

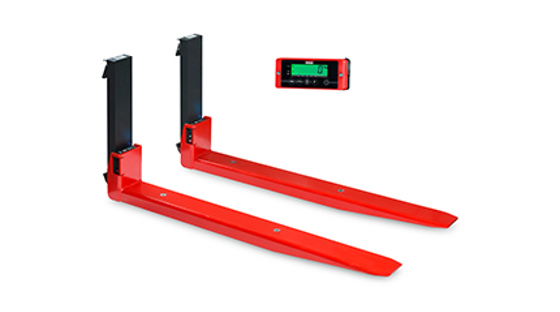

The iForks-32 are completely wireless weighing forks, optionally with data communication.

RAVAS Integration Software provides a two-way communication between a mobile weighing system and a WMS/ERP system.

How it works

An example

Let's say supermarket X orders 1000kg bags of potato chips from Frit Ravich. Frit Ravich takes a pallet or big bag of 1000kg of potatoes, weighs it, and then takes it to the water, salt and roasting process. At the entrance to each process, the goods are weighed again, as the weight can vary. The processes use metal tanks with an assigned bar code. Thanks to this, the kilos transported are registered through the RAVAS Integration Software in the Frit Ravich Warehouse Management System. By knowing the amount of residual raw material after washing with water, the salting process and subsequent roasting, Frit Ravich is able to optimize its manufacturing process by using the exact amount of each ingredient without having a shortage or surplus of end product.

About Frit Ravich

Frit Ravich is a manufacturer from Girona that distributes snacks, sweets and nuts nationally and internationally. It is a family business with 1000 employees, 7000 product references and thousands of customers from the retail industry and supermarkets. If you're a fan of FC Barcelona, you may be familiar with them because you've seen their crest on their bags.

About the application

Batching and dosing

When producing batches of semi-finished or finished product, the aim is to correctly mix the different ingredients and components. Amounts and proportions determine the quality of the product. A mobile scale helps you to produce cheaper, safer and more efficient. It also generates the information you need for quality control and tracking and tracing procedures. The scale is brought to the components: on a hand pallet truck scale the mixing vessel is driven from one ingredient to the next and components are dosed straight from their container. The risk of damages and product loss is greatly reduced.

Follow us on LinkedIn