RCS hydraulic load indication system

Simple weight checks

Easy installation via T-coupling

An oil pressure sensor is installed onto the hydraulic circuit of the forklift utilizing a T-coupling. The indicator in the cabin translates the measurement into a weight indication of the load on the forks.

Limited accuracy

The RCS has limited accuracy, with a possible error of maximum 2% of the truck's lifting capacity. The system is meant for simple check weighing, such as the checking for incoming goods.

Simple applications

The RCS is mainly used to simply check weight and avoid the overloading of lorries, warehouse racking and the forklift truck itself. Also suitable for rough applications.

For forklift trucks

RAVAS supplies a complete range of hydraulic scales for mounting on forklift trucks, regardless of the brand, make or model.

- Weighing capacity

- 2,500, 5,000 or 10,000 kg

- Graduation

- 10 kg at 2,500 kg, 20 kg at 5,000 kg, 50 kg at 10,000 kg. Higher capacity till 99 tons on request.

- System tolerance

- 2% of system capacity

- Prtoection class

- IP65/NEMA 4

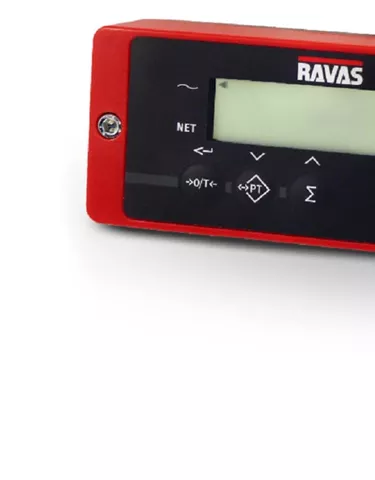

- Display

- LCD, digit height 18 mm

- Technical Specifications RCS

- Manual RCS

- Download PDF

More information about the RCS hydraulic scale?

Contact usAsk our specialists for more information or a quote on the RCS Scale.

Interested in the RCS?

Ask our specialists for more information or a quote on the RCS Scale.