"We used to need two hours every day in order to execute weighing. Now that is only one hour."

- F. HILLUS, FOREMAN

Weighing chemical products for book keeping of dangerous goods

Henkel produces chemical products, adhesives and detergents like Persil. The centre for Research & Development of the Chemical Division is based in Düsseldorf. This is where new products are developed and where existing products are enhanced and made more environmentally friendly. In order to measure the results of test samples, to maintain the book keeping of dangerous goods and to send chemical products to customers, weights have to be registered. Both in the Technicum – where products are developed and tested - as in the warehouse this is done in explosion proof areas.

Determine tare weight

Barrels and pallets were placed and weighed on a fixed scale. Often these had to be positioned manually to get the most accurate read out. This was very heavy work. In order to determine the tare weight, the barrel had to be emptied and weighed again.

The net barrel weight was calculated. The goods were then moved to the laboratory or warehouse.

Large gains of time and handling

The procedure with RAVAS:

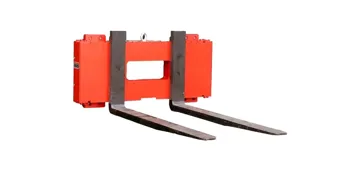

An EX fork lift truck has been equipped with RAVAS weighing carriage plate (model RVL). The intrinsically safe weighing indicator is mounted in the cabin. The power for the indicator is supplied by the EXi battery. Due to its compact construction the system is very easy to install. It also does not require any changes to the fork lift truck. Barrels and pallets are weighed directly at the place where they will be used or picked up for transport. This results in large gains of time and handling.

COMPANY

Henkel

LOCATION

Düsseldorf, Germany

APPLICATION

Stock control

Stock control

With global supply chains that stretch across continents, with small stocks and just-in-time deliveries, companies have become very vulnerable to stock shortages. Shortages mean interrupted production processes, delays, loss of customer confidence. And they all come with a cost. With a mobile scale, connected to your ERP or WMS system, material flows can be monitored every time goods are moved: inbound goods, goods in and out of production, outbound goods. Without interrupting the process, mobile scales allow you to accurately control your stock, reduce stock levels and lower cost.